Question

Which of the following is a wastage controlling

technique which means continuous improvement?Solution

Kaizen, means continual improvement. Continuous improvement is the continual examination and improvement of existing processes and is very different from approaches such as business process re-engineering (BPR), which seeks to make radical one-off changes to improve an organization's operations and processes. This philosophy implies that small, incremental changes routinely applied and sustained over a long period result in significant improvements. The kaizen strategy aims to involve workers from multiple functions and levels in the organization in working together to address a problem or improve a particular process. Some of the activities in the kaizen costing methodology include the elimination of waste in the production, assembly, and distribution processes, as well as the elimination of work steps in any of these areas.

{5% of (20 × 25) + 6% of (30 ×35)} ÷ 11 = ?

? = 120% of (652 ÷ 132 ) + 33 × 8

[{70 + (40 - 22) ÷ 3} ÷ 4] = ?

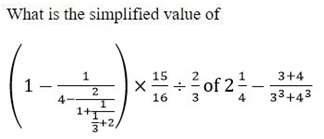

Find the simplified value of the given expression.

(1/4) of {64 - 28 x 15 + 13 x 16 - 12.5 of 122}

What will come in the place of question mark (?) in the given expression?

642 - 362 = ? X √1225

? = 6.25% of 240 + 252 + 172 – 16 × 17

- What will come in place of (?), in the given expression.

144 ÷ 12 + 18 × 2 = ? What will come in the place of question mark (?) in the given expression?

(50 × 6 ÷ 12) × 9 = ?

25639 – 5252 – 3232 = ?